This week I learned that the German government has launched a program named Industry 4.0.

I’m used to see terms as “4.0” in the www, but no in other industries. Then I learned there is a clear definition of the different phases of the industry revolution. We are now in the 3.0 and navigating to the next one.

How? Well, I do not know the other countries, but Germany has a roadmap and four pillars to go on the next phase of the manufacturing revolution.

A very good document I have to read is this one.

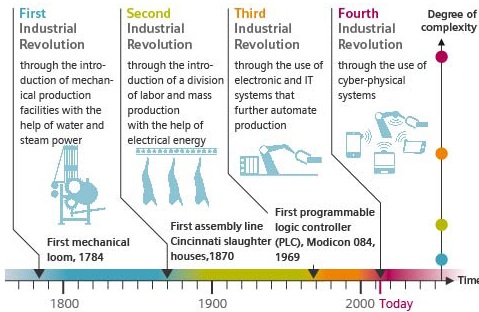

The first three industrial revolutions came about as a result of:

The first three industrial revolutions came about as a result of:

- 1st revolution: mechanization,

- 2nd revolution: electricity,

- 3rd revolution: IT.

Now, the introduction of the Internet of Things and Services into the manufacturing environment is ushering in a fourth industrial revolution. In the future, businesses will establish global networks that incorporate their machinery, warehousing systems and production facilities in the shape of Cyber-Physical Systems (CPS).

Cyber-Physical Systems comprise smart machines, storage systems and production facilities capable of autonomously exchanging information, triggering actions and controlling each other independently.

The vision is to build smart factories that improve to the industrial processes

involved in manufacturing, engineering, material usage and supply chain and life cycle management.

Smart factories will promote:

- Individual customer requirements.

- Dynamic business and engineering processes: enable last-minute changes to production and deliver the ability to respond flexibly to disruptions and failures on behalf of suppliers, for example.

- Optimized decision-making process.

- Address resource and energy efficiency.

- Urban production.

- Demographic change.

The Industrie 4.0 Working Group believes that action is needed in the following eight key areas:

- Standardization and reference architecture.

- Managing complex systems.

- A comprehensive broadband infrastructure for industry: Reliable, comprehensive and high-quality communication networks are a key requirement for Industrie 4.0. Broadband Internet infrastructure therefore needs to be expanded on a massive scale, both within Germany and between Germany and its partner countries

- Safety and security.

- Work organization and design: the role of employees will change significantly, implementation of a socio-technical approach to work organisation will offer workers the opportunity to enjoy greater responsibility and enhance their personal development.

- Training and continuing professional development.

- Regulatory framework: protection of corporate data, liability issues, handling of personal data and trade restrictions.

- Resource efficiency.