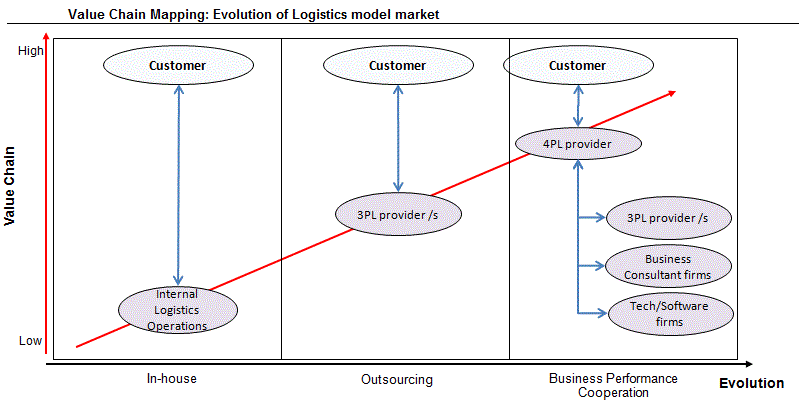

I’m working on a logistics transformation, and it is letting me know the situation of the market with respect the logistics business, where all come from and where all go…

Nowadays so many companies outsource part of the processes, typically IT and keep the management activities inside the company. The main question done before to move to 4PL is: who needs to be in control of the supply chain, and who can manage it better?

- In 3PL model, logistics is considered a core process and it’s managed by the company.

- In 4PL model, logistics is considered a key process and it’s managed by a third party.

A 4PL functions more like an internal logistics organization, whereas a 3PL may focus on specific logistics activities. Think of a 4PL as an orchestra conductor, working to bring together the best-in-class components of a world-class supply chain. It means in some way to be a part of the company’s supply chain, not a vendor in the list.

The 4PL company defines a strategy and implements it.

This is a big change for manufacturing companies, which have had logistics always as one of the core processes in their organizations.

A 4PL has mainly three key goals:

- Driving the spend of improvement for the organization.

- Increasing the supply chain competency.

- Waste elimination.

This trend continues evolving, there are so many 4PL organizations that are able to demonstrate the value they provide and the competitive advantage they offer to the manufacturing companies.