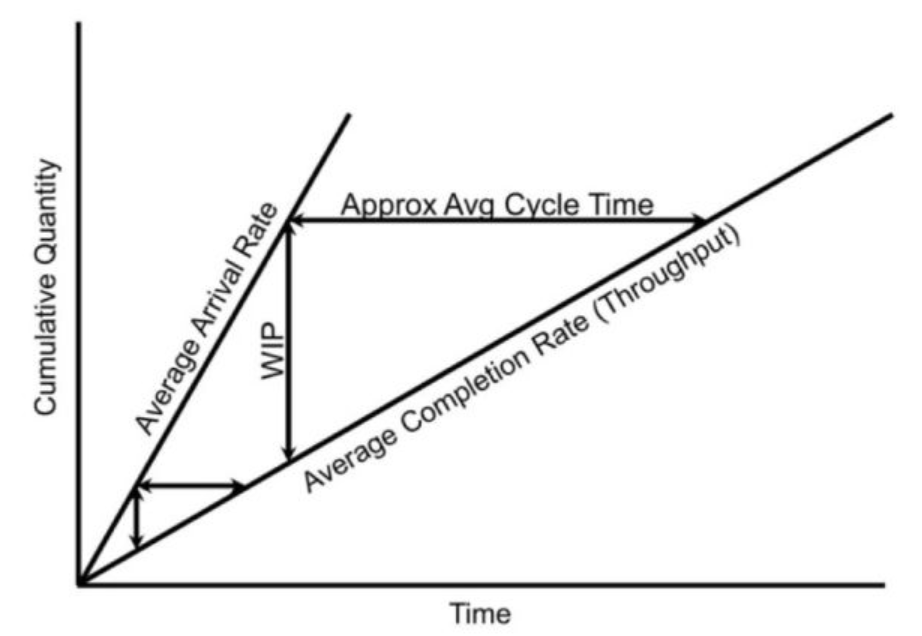

Little’s law is widely used in manufacturing to predict lead time based on the production rate and the amount of work-in-process, and since Kanban practitioners use it in software development is becoming more and more popular.

In fact the comparison for the outsiders of a manufacturing example where things are more tangible is something that helps them a lot.

The testing software scenario

I’m going to use a simple testing scenario of a software that is moved to production frequently.

- Use case test = I will call it “test” that is composed by a set of unit tests. For instance a use case could be composed by 20 unit tests, other use cases could be composed by 50 unit tests.

- Unit test: It’s the unit of work we can measure. The average time to perform it is 30 minutes. Every time a use case is requested to be sent to production it needs to pass all its unit tests.

- Testing group capacity = 8 people performing 14 tests per day which means 112 tests per day.

Little’s Law tells us that the average number of unit tests L, is the effective performance rate λ, times the average time that an unit test takes to be performed W, or simply: L = λ x W

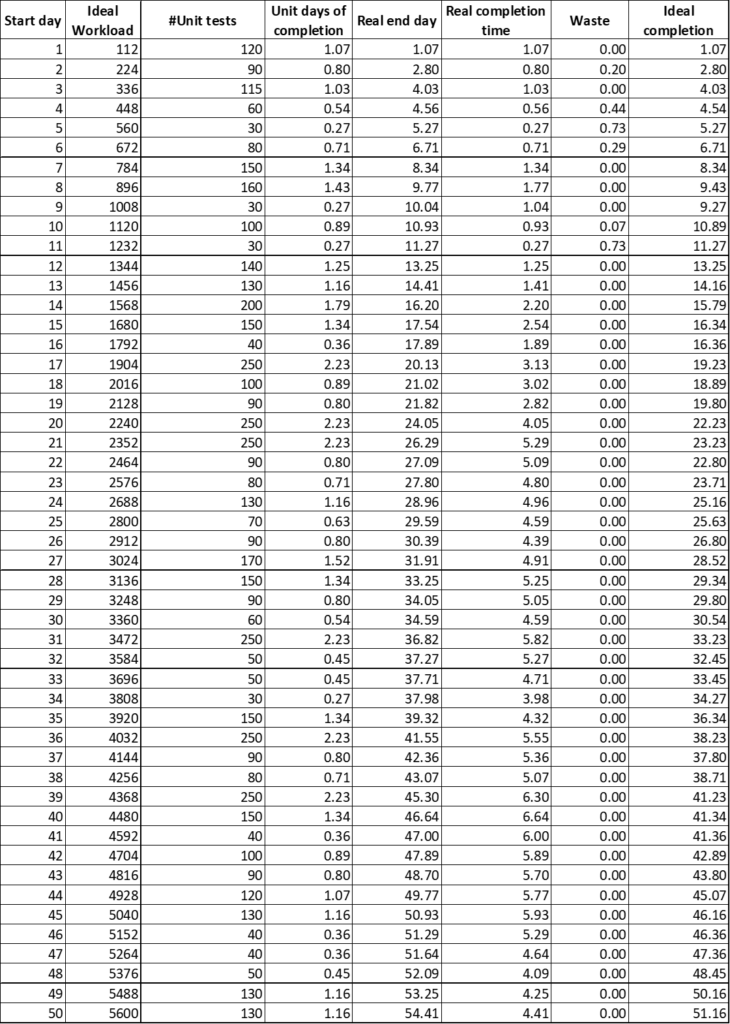

Data table

Let’s take this data as reference

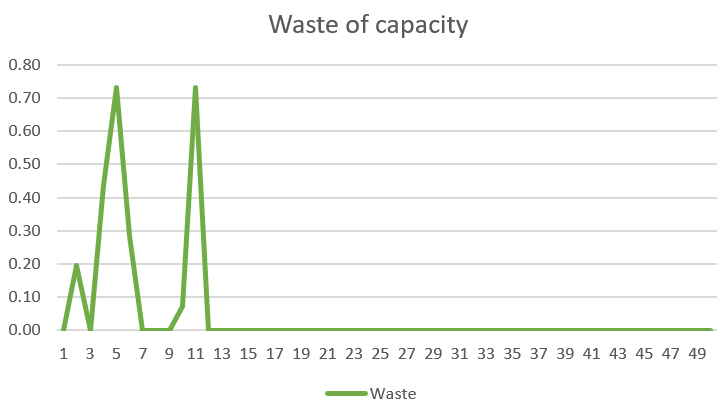

We can see that in the beginning we have some waste of capacity:

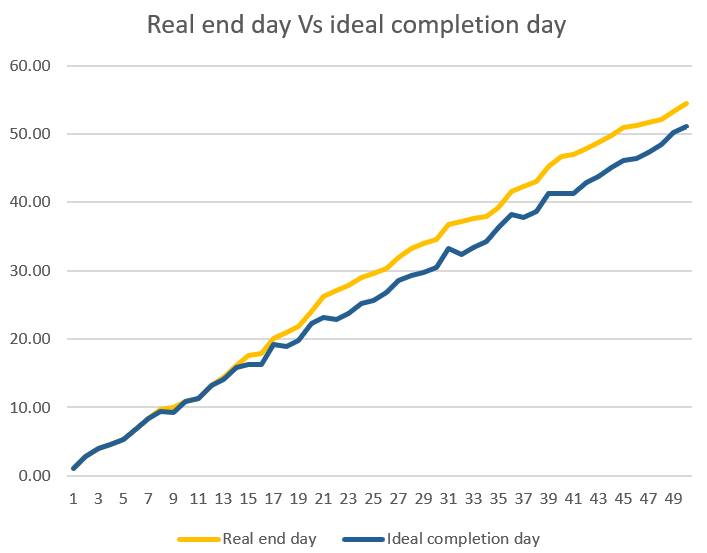

We can see the λ (lambda) clearly on the chart, provoked by the Work in progress (WIP) that already exist.