Techniques, there are different techniques and components that once they are summed, you can calculate the cost of poor quality.

Criteria, it is very important to define the criteria and highlight the arguments that compounds the measure of the COPQ. This calculation generates always controversy because depending of the components used it will point to a group of people more or less as the ones causing the issue (this item is not a cause of poor quality, or yes it is…)

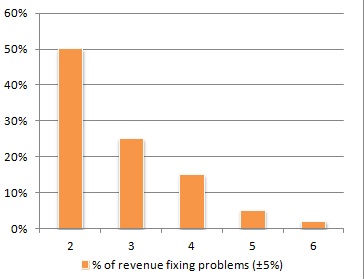

A reference is required in the situations where you are not able to calculate an accurate COPQ. These market references help to do a rough order magnitude estimate. I found this one:

- Companies operating at three or four sigma typically spend between 25% and 40% of their revenues fixing problems.

- But companies operating at six sigma typically spend less than 5% of their revenues fixing problems.