Warning! the interesting part comes after the list, on next

I looked for job descriptions for a “Supply Chain Director” role focused on Manufacturing in United States. This is the list of responsibilities which are requested:

- Design and manage the core supply chain processes, supporting the business supply Chain teams in implementation.

- Ensure governance of the core supply chain processes working with the business operations to continuously drive enterprise-wide improvements.

- Provides a global standard and view on planning processes and inventory management

- Owns and facilitates central operating processes that reach across the enterprise on inventory management and raw material allocations.

- Act as a key part of the Integrated Business Planning process and is responsible for escalation of key decisions that reach across the business.

- Represent the voice of the Global Supply Chain in the regional planning processes.

- Partners closely with the Supply Chain directors in each region and business unit as well as Procurement Directors.

- Leads a global team of subject matter experts.

- Develop or source new software solutions for the Supply Chain department

- Customize ERP system’s functionality to best serve department needs

- Monitor KPIs to provide comprehensive reports, analytics and visibility around product supply status to all key stakeholders

- Research and recommend improved methodologies, tools and software for demand planning

- Review inventory levels and ensure periodic inventory optimization based on business forecast and goals (including reducing any slow moving and obsolete inventory)

- Monitor, analyze, make recommendations and implement planning processes regarding cash flow forecasting

- Be accountable and responsible for the overall strategy and relationship building with 3PLs and vendors, at times requiring international travel

- Design the distribution network

- Negotiate annual product costs, factory incentives, optimal MOQs, inbound freight rates/carriers and customs brokers

- Set standards and drive performance for team, mentoring and modeling tasks for Supply Chain Analysts as needed

- Prepare and conduct executive-level presentations including demand analysis, capacity utilization and cost scenarios to facilitate thoughtful management discussion and drive effective decision making

- Identify and develop key talent to ensure success of all individuals in the department

- Create, develop, and provide leadership & oversight to a geographically diverse supply chain team.

- Develop and execute strategies that drive continuous improvement and progression.

- Plan, manage, and coordinate all activities related to purchasing, customer service, warehouse, and logistics.

- Define, manage, and report on supply chain KPIs

- Define Plan For Every Part (PFEP) for RAW, WIP, and Finished Goods materials

- Includes development of value chain process of raw materials detailed analysis of procurement needs and identifying opportunities. Refine work processes in support of Supply Chain strategy, and leveraging opportunities and realignment of specific raw material purchases with other categories.

- Develop and maintain internal relationships where you will be the Single Point of Accountability of your area.

- Be an active part of the management team who continuously strives for excellence and sets the example for work ethic and dedication

- Oversee procurement, material forecasting, planning and inventory management

- Manage plant scheduling and line sequencing focusing on customer service and efficiency

- Manage medium term raw product planning by interfacing between the main growing partners and the sales team

- Act as liaison between Sales, Marketing, Operations, and Supply Chain to help determine improvement project priorities and timelines

- Oversee short term raw product planning including forecasting, ordering and inventory management

- Oversee finished good forecasting, planning and inventory management

- Assist in developing relevant processes and policies as needed by our customers

- Aggressively pursue and create competitive purchase environment by constantly seeking alternate supply scenarios

- Establish and maintain business relationships with the appropriate management of key suppliers

- Utilize available e-Sourcing tools/Spend Analytics (potential adoption)

- Resolve process or supplier related issues as escalated from the Businesses where the tactical teams need support

- Maintain knowledge of suppliers and relevant market developments such as mergers & Acquisitions, financial status, and changes in key personnel

- Provide strong leadership and development of a team of Directors and other key leaders

- Responsible for enhancing department operating leverage and ensuring appropriate resource allocation

- Influence change within department, peers and stakeholders consistent with the company purpose and values

- Travel is required

- Lead the Demand Planning and S&OP Operations to ensure a high level of forecast accuracy for both the short and long term.

- Develop and maintain the company sourcing and purchasing strategy including commodity management, vendor selection and evaluation, contract management, competitive sourcing, and material planning. Total annual spend is more than $250M.

- Management of the inbound material planning group to ensure consistent material availability to meet manufacturing demand.

- In addition to management of the material planning team, the VP of SCM also finalizes and manages the production planning schedule as dictated by the demand plan.

- Oversight of both the finished goods and raw materials warehousing operations.

- Daily management and oversight of the customer service and outbound logistics group with an emphasis on quality service and cost management.

- Develop and maintain the policies and structure necessary to ensure optimum supply chain for achieving company goals and objectives.

- Drive the development of analytical tools and reports to effectively manage supply chain performance KPI’s across the company.

- Lead ongoing efforts to achieve continuous improvement of the supply chain function through evaluation of new technologies and industry best practices.

- Drive engagement by building and developing a high-performance team that consistently delivers Supply Chain KPIs.

- Accountability for management of all Supply Chain related budgets including procurement spend, PPV, 3rd party logistics, carriers, etc.

- Lead a staff of 7 direct and 70 indirect reports across multiple facilities.

- Develop and implement inventory strategies and processes in alignment with multiple channels, department plans, key inventory targets, and financial goals

- Innovate reporting and analytics to identify working capital inefficiencies

- Lead inventory escalations with the executive team in IBP/S&OP and Performance Reviews

- Drive streamlined inventory planning policies to support product lifecycle; new product launches and sunsetting

- Develop short- and long-term tactics that support the financial working capital strategies

- Lead upstream supply chain inventory initiatives by partnering with strategic sourcing and manufacturing teams

- Evaluate and assess key indicators such as service level, forecast variability, and performance objectives to reduce and control cost

- Continuously improve our Employee Safety systems, identify issues and solve them, and drive for a Zero mindset on employee injuries

- Assure our Food Safety and Quality systems are in place, and overdeliver customer expectations

- Work with our supply chain team to identify capacity constraints and make sure we can deliver our promise to our customer of 98.5% level customer service every month.

- Implement our Guenther Performance Systems, our Lean approach to Manufacturing and drive proactive communication throughout every level of the organization.

- Leverage our GPS approach to lead by example out on the floor and calibrating teams on performance where they work

- Deliver 3-5% cost savings annually through identifying and executing projects to improve OEE, reduce product waste, reduce unnecessary costs, etc.

- Create and drive annual business plans on People, Safety, Quality, Service and Costs

- Lead the Plant teams and make sure everyone has clear goals, objectives and expectations on performance, and calibrate the team on results regularly

- Monitoring daily operation schedules for all departments for accuracy and ensuring daily operational goals are realized

- Provide strategic guidance to the organization through participation in cross functional meetings and data analysis on sales trends and cost performance.

- Create a 3 – 5 year strategic plan for the facility that assures supply and maintains infrastructure needs, and can support the organizations growth strategy

- Improve the facility stewardship and asset maintenance

- Participate in new product development and planning by researching the cost and ability of producing the product

- Lead the implementation of new product implementation for the facility.

- Adhere to the approved operations annual budget and provide budget updates and adjustments as requested by Vice President

- Develop and execute replenishment strategy for the North American division of the business, working closely with sales, strategic sourcing, demand planning and operations to drive overall success.

- Champion and advance the Sales, Inventory & Operations Planning (SIOP) process, developing and implementing inventory and replenishment purchasing strategies to meet commercial and business objectives.

- Oversee the replenishment purchasing process where the purchasing team executes the purchasing strategy to match the outputs of the SIOP process.

- Oversee the demand management process in synthesizing sales and customer data to generate an accurate forecast to drive optimal buying activity and inventory levels.

- Work closely with Strategic Sourcing to implement supply chain strategies & manage day to day supply issues.

- Streamline procurement processes with efficient use of systems and other tools according to best practices.

- Identify procedural and internal control gaps and implement appropriate solutions.

- Ensure that all system generated planning tasks are executed and all system data is maintained.

- Monitor purchase price variances and implement corrective actions.

- Evaluate and optimize the supply chain network design to improve business performance.

- Coach and develop staff through on-boarding, open communication and training and development; implement talent development and succession plans.

- Work with business intelligence team to manage and further develop key performance indicators (KPIs) and dashboards to measure and drive supply chain performance.

- Work with finance team to connect inventory and replenishment strategy to business objectives.

- Drive a culture of continuous improvement.

- Manages all operations of the assigned Infant Formula manufacturing/packaging facility, ensures that all operations comply with current Good Manufacturing Practices, oversee pre-treat water facility, to assure compliance with all applicable regulations; reviews and approves Standard Operating Procedures for all plant operations, and monitors training and enforcement to ensure SOPs are followed. Assures site Compliance with all regulatory requirements. Developing and maintaining relationships with Town official is critical to the success of the facility.

- Supports the strategic goals through effective and efficient project management for ongoing delivery of operations/production activities and processes.

- Provides leadership and technical support for operations/production team to support infant nutrition.

- Manages operating activities and ensures products are manufactured/packaged on schedule and are within quality standards and cost objectives.

- Develops staffing and cost proposals for the fiscal year, and monitors costs and productivity throughout the year to ensure production goals are met. Monitors all training and provides development opportunities to plant staff and coaches.

- Provides leadership to safety efforts within the plant, monitoring safety performance and ensuring coaches provide appropriate training and direction to provide a safe working environment.

- Ensures compliance with company policies and rules of conduct and addresses performance issues appropriately and promptly.

- Incumbent provides leadership in process improvement, working with engineers, supervisors and other production support staff to improve processes procedures and/or evaluate equipment.

- May lead one or more teams responsible for operations management.

- Establishes performance metrics for measuring, comparing, or evaluating factors affecting the supply chain, production, and logistics.

- Develops and maintains detailed inventories of materials and supplies located in the company, at sites, and in the factory.

- Holds the required quantity of supplies and materials to optimize production.

- Analyzes current inventories and procedures; suggest improvements to increase the

- efficiency of the supply chain and profitability for the company.

- Develops policies to increase efficiency throughout the supply chain while ensuring quality; implement subsequent changes to processes.

- Develop internal and external quality standards to ensure product quality and safely.

- Identifies optimal shipment and transportation routes with attention to consolidating warehousing and distribution.

- Negotiates prices for raw materials and delivery with suppliers and shipping companies.

- Participates as an advisory member of the product development team, providing information and guidance on the availability and cost of supplies and materials.

- Acts as part of the team coordinating engineering changes, product line extensions, or new product launch to ensure timely and orderly material and production flow transitions.

- Monitors the performance of suppliers, assessing their ability to meet quality and delivery requirements; identifies and qualifies new suppliers in collaboration with other departments.

- Assists chief operating officer with long-range operating goals, expansion efforts, and implementation of new and advanced technology.

- Oversee the production manager and logistic manager to plan and organize production and delivery schedules.

- Continuously improve our Employee Safety systems, identify issues and solve them, and drive for a Zero mindset on employee injuries

- Assure our Food Safety and Quality systems are in place, and overdeliver customer expectations

- Work with our supply chain team to identify capacity constraints and make sure we can deliver our promise to our customer of 98.5% level customer service every month.

- Implement our Guenther Performance Systems, our Lean approach to Manufacturing and drive proactive communication throughout every level of the organization.

- Leverage our GPS approach to lead by example out on the floor and calibrating teams on performance where they work

- Deliver 3-5% cost savings annually through identifying and executing projects to improve OEE, reduce product waste, reduce unnecessary costs, etc.

- Create and drive annual business plans on People, Safety, Quality, Service and Costs

- Lead the Plant teams and make sure everyone has clear goals, objectives and expectations on performance, and calibrate the team on results regularly

- Monitoring daily operation schedules for all departments for accuracy and ensuring daily operational goals are realized

- Provide strategic guidance to the organization through participation in cross functional meetings and data analysis on sales trends and cost performance.

- Create a 3 – 5 year strategic plan for the facility that assures supply and maintains infrastructure needs, and can support the organizations growth strategy

- Improve the facility stewardship and asset maintenance

- Participate in new product development and planning by researching the cost and ability of producing the product

- Lead the implementation of new product implementation for the facility.

- Adhere to the approved operations annual budget and provide budget updates and adjustments as requested to Vice President

Context and purpose

This is an experiment related to a research we are doing about manufacturing industry. Warning: as first experiment the outcomes are not clear.

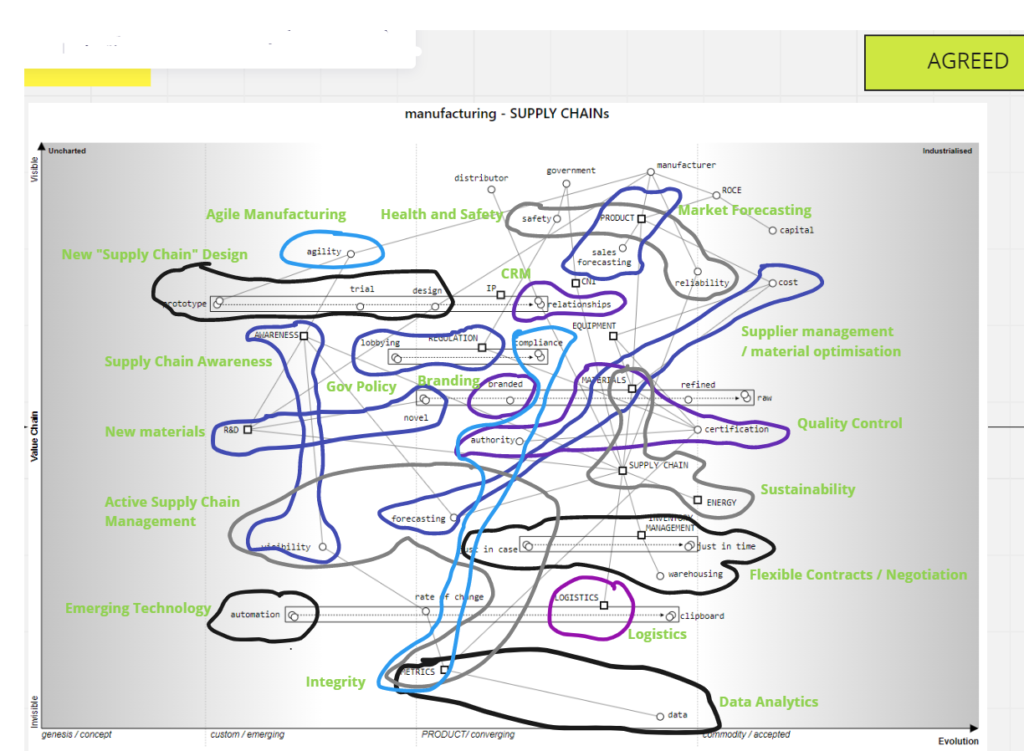

The context is related to a research we are doing on manufacturing industry. After weeks of work we have agreed on this map as good model of the reality:

The circles are potential areas of investment we believe will happen. The point is that after the conversation we have to look for data that support the hypothesis.

- Financial data,

- Published articles,

- etc

My approach is look for data in other places. In this case my hypothesis is:

- The companies itself do not work with trends, they work with issues, concrete plans on their roadmaps and commitments with their shareholders (those who are public).

- They have to hire people to drive these plans.

- The hire people through job vacancies that are published publicly.

- The job descriptions do not disclose all information, but they maybe gives some clarity.

So let’s try it.

Experiment 1: looking for future responsibilities on job descriptions related to “Supply Chain Director” role

- I have collected this list of responsibilities for jobs titled “Supply Chain Director”

- Data election data: 10 jobs published in LinkedIn, under manufacturing companies, location = United States, date range = last month.

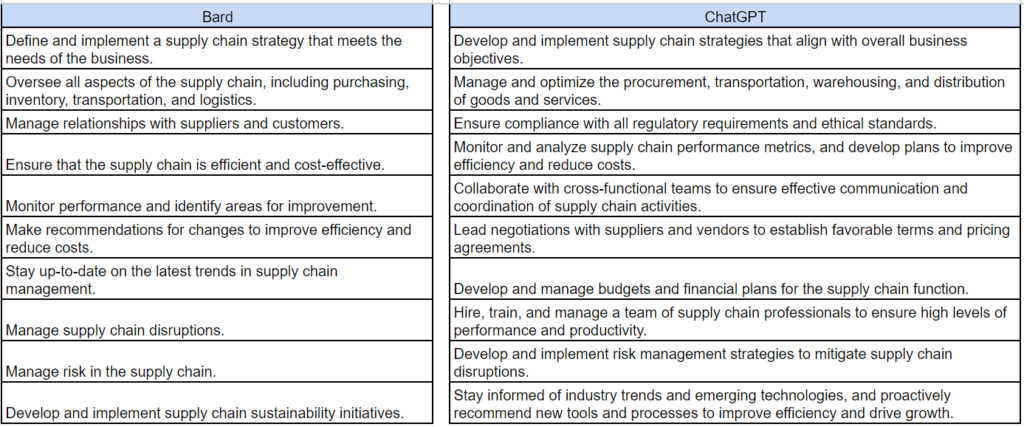

- I have given the link to ChatGPT and Bard.

- I have asked both: Based on the list of responsibilities I provided you in the link, I would like to know based on that list, what are the 10 main demanded responsibilities.

The answers respecting the order provided by each one:

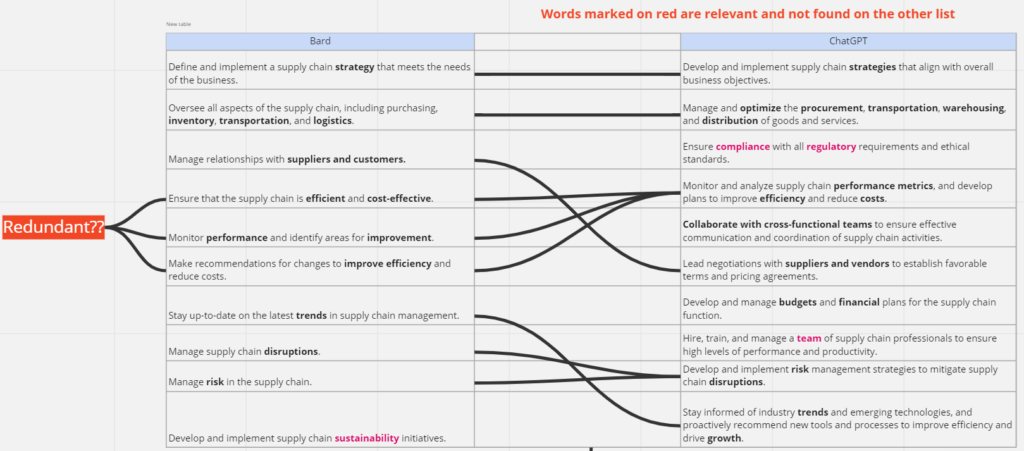

I have highlighted the data in a different way to try to compare the answers:

Do you extract any learning from the comparison?