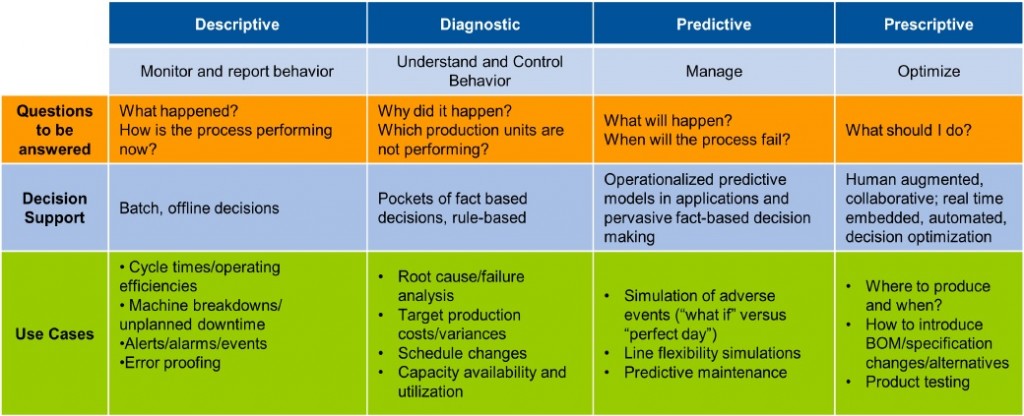

I assisted to this Webinar presented by Gartner, and the more interesting part of the conversation was when the discussion was on this table:

One of the figures commented during the event was that 70% of the data the manufacturing companies have is not used. There is still so much progress in terms of metrics that can be done.

One of the figures commented during the event was that 70% of the data the manufacturing companies have is not used. There is still so much progress in terms of metrics that can be done.

For descriptive, diagnostic and prescriptive metrics the companies have so much in place and the maturity is good. But in terms of predictive metrics, here in the same way that retail companies are already analyzing the behavior of the consumers, the manufacturing companies can still open the use of prediction to look for benefits in terms of quality, time response and quality.

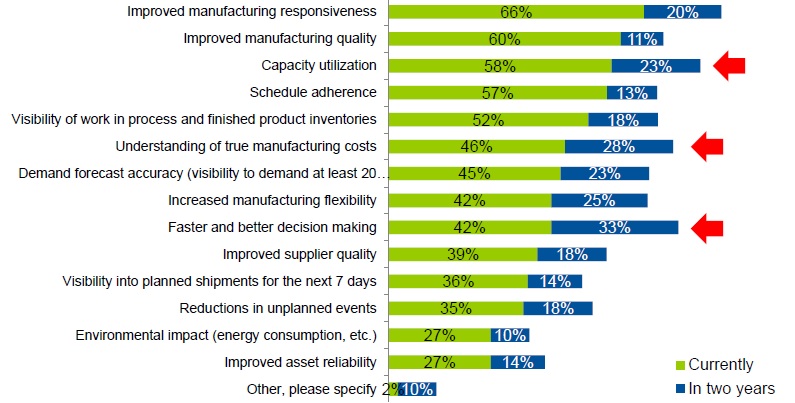

On the survey done to 83 people from the sector, there was a question:

In which areas is your organization planning to drive business value from the use of manufacturing metrics currently and over the next two years?

The answer was:

The 4 areas that are in the minds of more people are:

The 4 areas that are in the minds of more people are:

- Capacity utilization.

- Understanding of true manufacturing costs.

- Faster and better decision making.

- Demand forecast accuracy.

The question that came to my mind was:

how can predictive metrics help to the business to improve these four areas?

My thoughts:

- Capacity utilization: here predictive metrics can have an important impact.

- Understanding of true manufacturing costs: here what we have to analyze is the past, not the future. Diagnostic metrics are more useful.

- Faster and better decision making: here predictive metrics can have an important impact.

- Demand forecast accuracy: here again diagnostic metrics are more useful.