Background

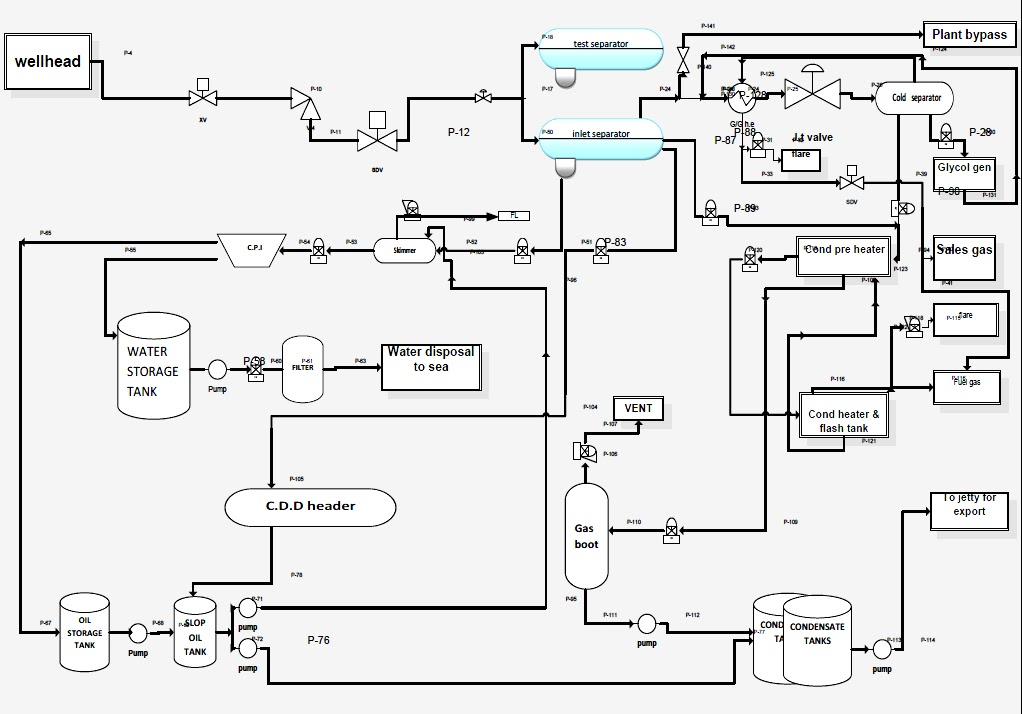

If we look at a gas factory, you will find thousand of pipelines with different pressures and gas cocks that can be adjusted to maximize the outcome of the factory.

Each section of the gas factory has its own pressure requirements and the amount of gas managed by each section is different.

Many modern organizations are in some way like a “gas factory”. I mean:

- They are build by different business units and teams.

- The organization make decisions based on administrative criteria.

- Sometimes the formal approvals takes time, effort and gaps on the understanding about what is decided.

- Sometimes the formal approvals are dynamic and well performed, providing authority and visibility about what’s being done.

- These teams make decisions under professional criteria, under guiding principles and processes.

- Collective decisions are also part of the organization, specially when they are cross functional.

- These teams have individual purposes and different ways to work; and it’s fine in that way.

- Sometimes the factory is old, some other times the factory size is growing up, some other times the factory is too much big. There is not perfect gas factory.

- Your gas factory is in reality a supply chain composed by components of different nature that need to flow as the gas in a gas factory.

The problem

The leader of the “gas factory” has a purpose, and to achieve it s/he needs to drive the organization into one direction. This strategic direction can be defined, but them it needs to be executed.

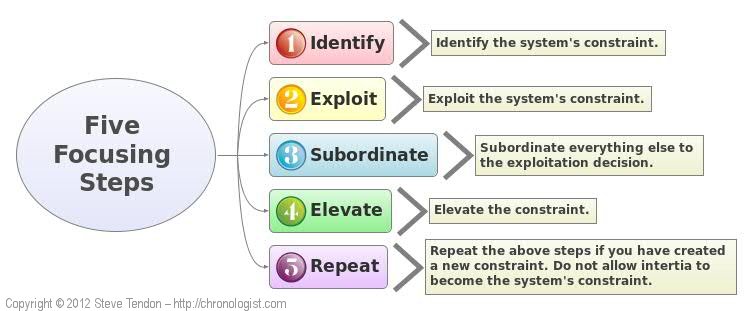

The execution of the strategy is a complex process full of decisions that have consequences. If you have read The Goal , then you probably remember this diagram:

The concept of the diagram above, gives you an idea about the mental model you can implement to figure out how to make decisions. The Goal is a good book, I like it, but the narrative pass over various important factors:

- The context needs to be understood in detail by some people and with enough perspective by others.

- This context is evolving in different parts of the fabric, is not static.

- You need data, not only of the incoming data, but data about the consequences of the changes you have implemented (if you move a gas cock, there will be pressure consequences in other part of the factory) and environmental factors will show up too.

- The bottlenecks are present in many parts of the factory, to tackle them one by one is something not realistic.

How can I drive my “gas factory” into the right direction?

I don’t know, the solution depends on the context and I have not context here. What I can propose to you is a mechanism that helps you to learn and make decisions.

The proposed mechanism takes into account different things:

First, let’s get perspective

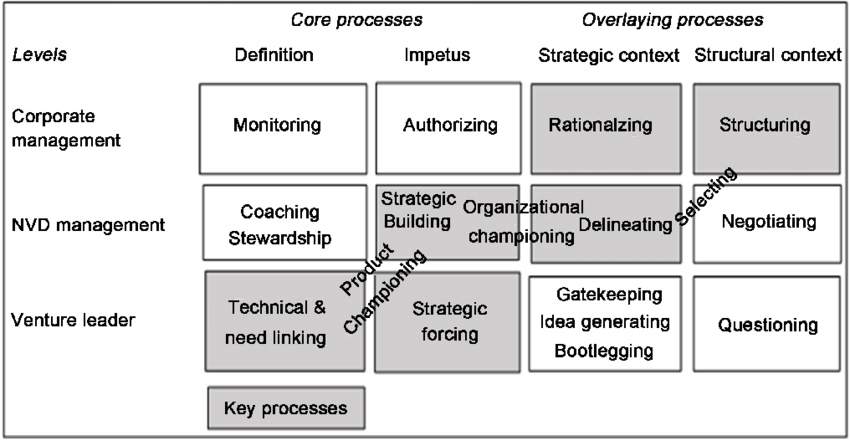

I will take the support of the Burgelmans process model of internal corporate:

Where you will find the following levels:

- Corporate management: it’s where the gas factory lead or team is looking at the performance of the factory and are trying to understand.

- Their focus is to monitor and control the capital flows (money, resources, priorities, etc.).

- They provide principles, rules and structure to the organization. This is done through authority.

- Their main duty: monitor, recognize patterns and make structural decisions.

- New venture development (NVD) management: They are provided with the guardrails, rules and capped free of movement to achieve their goals.

- They are the people understanding the user needs, their own capabilities, the competitive scenario they have with respect other competitors, partners and stakeholders.

- They are the ones that can make strategic decisions about their own businesses.

- They negotiate to achieve goals (outside and inside the organization).

- Venture leader: Understand the details, evaluates its own context with the other contexts close to him/her.

- Challenge and question the status quo and make decisions to unblock and advance towards its own purpose.

- Understand the limits defined by corporate management to play the game.

- Depending of the style, s/he will play with these limits.

The view of each level is different, and you, that are at corporate level trying to get control of your gas factory need to understand the context and identify patterns into the factory.

Second, what is the main thing to measure?

Corporate management’s first metric is the finance performance, by that reason the capital expenditure, revenue, margins and other financial metrics are the ones that be prevalent during the monitoring process.

If your gas factory belongs to other environment: non-profit organization, political environment, etc. then the main metrics will be different.

Third, build the context awareness

To build context awareness, my approach is to build maps.

- Each level builds their own Wardley map, and this view is shared in a psychological safety place.

- These maps are build by each one and they are not perfect, they are different and enable conversations to gain understanding about what is happening. These conversations are being hold by different units and levels.

- The conversations are not limited to the map; climatic patterns affecting the business, prevalent doctrines present in the teams, and gameplays being used are part of the conversation.

- The Wardley map represents a situation for a given moment. So it will be necessary to understand for each map the start situation and the next moment where the map is updated.

- The frequency of update in the maps differ. Some will be updated regularly, some others will be updated once a year. It’s done when it’s required.

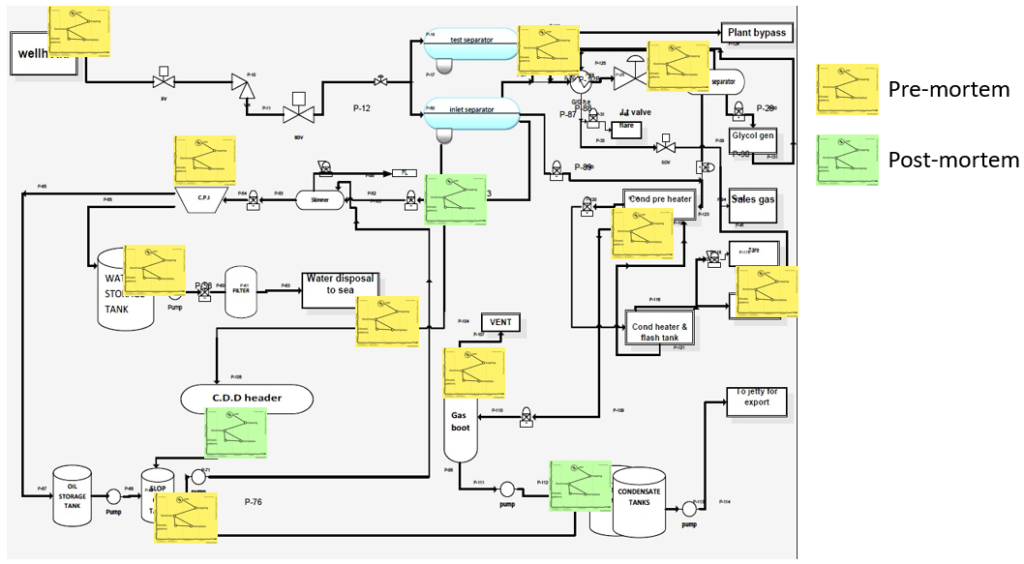

- The different moments where a map to provide context will be divided in 2 stages:

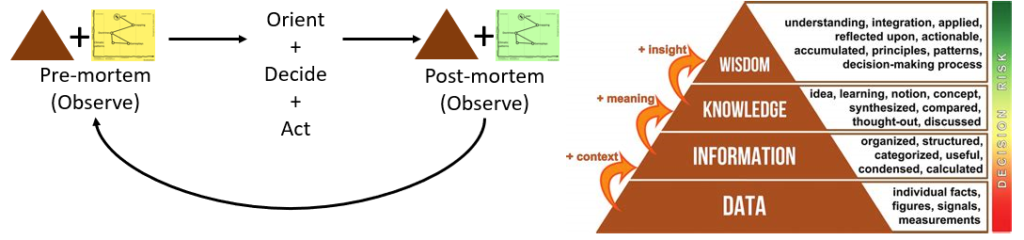

- Pre-mortem: moment in the timeline where we try to understand the context. Once the assumptions are decided, there is consensus about the scenario, then some decisions are done. Once done, we will look at the execution to try to recognize patterns.

- Post-mortem: moment in the timeline where you learn the consequences of the changes done, other external factors that affect your context (for instance climatic patterns), and gives you input to make the next set of decisions. Patterns recognition enable the leaders to understand better the context and dynamics, and define the next pack of principles, processes and incentives. The post-mortem analysis is indeed the next pre-mortem analysis too, it’s a step where we observe (following the OODA loop convention).

- Maps is just the beginning. The organization need different type of data to understand the reality of the business: finance data, business data, industry data…

- The maturity of the metrics, KPIs, OKRs and the data the organization is able to measure and digest is a complex topic that can be covered in many different ways.

Fourth, build an iterative process

The gas factory is running, and every quarter you will have finance results, business results and the need to understand what worked and what didn’t work.

I’m assuming quarters is a common check point for the majority of the companies. Despite the fact that some initiatives require more than 13 weeks to provide relevant outcomes, quarters is not a bad pace to stop and check some aspects.

The basic iterative process, supported by maps and data could be simplified to this:

The basic steps are something like this:

- The decisions at corporate level start understanding the major capital flow gaps.

- This will lead them to draw maps, analyze data, so they can understand the context.

- Once there is consensus about assumptions and context, leadership has to orient themselves and define a set of decisions.

- The decisions are distributed through the organization things will happen (action).

- After that, leaders will be able to measure the impact and check the capital flow behaviors again.

The continue monitoring of the organization performance is the main duty of corporate management.

The understanding of the the pipelines of your gas factory (your supply chain) is a continuous learning process that will enable them to recognize patterns and make better decisions in a better way.

Fifth, how are these mechanisms put in place in the organizations?

There are some standard ways used by the organizations to regulate the gas factory:

- Enabling Governance, Risk and compliance organization and processes.

- Enabling a business assurance organization and processes.

- Quality assurance organization and processes.

- Corporate services, as finance, or human resources provide mechanisms too for the implementation of guiding principles and processes.

- Incentives: the way you pay defines the way people will behave. To have good incentive mechanisms are key.

Depending on the company type (public or private), they have some regulatory requirements that force them to implement some standards to be compliance with the law of the country.

Give me an example about how the gas factory works

This is a not real example, but that can easily happen:

This time the gas factory will be a global engineering company that delivers infrastructure projects.

Sequence of events

- Corporate management detects that the productivity by X-factor per employee has decreased

- Corporate management decides to add some hurdles to hiring processes.

- These extra requirements provoke 2 things:

- Next quarter productivity has increased.

- Revenue growth has not meet the expectations.

- Corporate management reviews the situation. The first feeling is that sales is not closing deals.

- What they find is that deals have been closed, but the contracts have not started as there is not enough people to execute these contracts.

- Human resources review the rules added to limit the hiring so the productivity increases. They find out that the exceptions to the rules are not well defined. These exceptions are updated to enable better conditions that do not harm the revenue goals.

Closing

To lead a major organization is a tough duty and it’s full of mechanisms that you cannot control directly. It’s not you push button “3” and light “D” turns on. There are a lot of indirect mechanisms and external factors that happen around that ecosystem we call “organization”.

The role of the CEO is sometimes more the one of an alchemist than we think, and the decisions they commit takes time to be executed.